Areas of Research

Facilities

School of Chemical and Petroleum Engineering, Sharif University of Technology, Tehran, IRAN

POLYMER COMPOSITES RESEARCH GROUP

School of Chemical and Petroleum Engineering, Sharif University of Technology

School of Chemical and Petroleum Engineering, Sharif University of Technology

Biomedical

Soft electronics

Nanocomposite hydrogels as wearable strain/touch sensors

Nowadays, soft electronics have gained growing interest due to their widespread applications, particularly as wearable strain sensors that monitor human motions, or as self-powered touch panels that generates current either from deformation (based on different mechanisms such as piezoionic effect) or from rubbing (based on triboelectricity). As the flexible part of soft electronics, hydrogels are promising thanks to their features of skin-like softness, tunable toughness, intrinsic ionic conductivity, and self-adhesiveness. However, to endow hydrogels with high electronic conductivity, great strain/touch sensitivity, and remarkable mechanical performance, concurrent use of conductive agents and hydrophilic reactive fillers is needed.

.

Surface coating

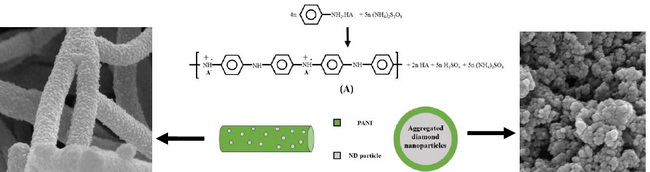

PANI/ND hybrid nanoparticle to improve corrosion protection of epoxy coating

In the present research, polyaniline (PANI)/nanodiamond (ND) hybrid nanoparticles were synthesized with different morphologies. These hybrid nanoparticles were incorporated into epoxy coatings and the corrosion protection of such coatings were investigated carefully by EIS. The investigation realized the synergistic effect of PANI/ND hybrid nanoparticles on corrosion protection of epoxy coating compared with PANI- and ND-containing epoxy coatings.

PANI/ND hybrid nanoparticle to improve corrosion protection of epoxy coating

In the present research, polyaniline (PANI)/nanodiamond (ND) hybrid nanoparticles were synthesized with different morphologies. These hybrid nanoparticles were incorporated into epoxy coatings and the corrosion protection of such coatings were investigated carefully by EIS. The investigation realized the synergistic effect of PANI/ND hybrid nanoparticles on corrosion protection of epoxy coating compared with PANI- and ND-containing epoxy coatings.

The research interests in Polymer Composites Research Group (PCRG) currently revolve around polymer matrix composites (PMCs) with advanced functional and structural applications. Overall, our attention is given to a wide range of PMCs with various types of reinforcements from micro- to nano-scale and from particulate to continuous forms. Various types of polymer matrices including single polymer or polymer blends of thermosetting resins, thermoplastics and elastomers are also taken into consideration in our research activities depending on the applications. Development of polymers and polymer (nano) composites for

Biomedical,

Energy storage, Environmental, Soft electronics, Friction materials, Responsive & smart materials, and Surface coatings

receive increasing attention in our group in view point of applications. A common theme in our research projects is to tackle to unearthing relationships between micro/molecular structure and macroscopic properties in PMCs as well as the development of novel hybrid nanostructured materials with synergistic behaviors to promote the performance of PMCs.

Due to the complexity of the morphology of composite materials originated from the morphological complexity of polymer matrices themselves, dispersion state of the reinforcing particles in polymer matrices and interactions at interface between polymer and particle in PMCs, correlation between the properties and the morphology has prime importance. In many cases, the reinforcing particles (particularly the nanoscale particles) have dominant role on the morphological features of polymer matrices such as the crystallinity and trans-crystallinity, morphology of polymer blends, promotion of immobilized polymer layer at interface. To overcome difficulties associated with morphological issues of PMCs, we focus on tailoring surface chemistry of reinforcing particles and controlling processing techniques. A basic knowledge on the structure-property relationship enables us to understand fundamentally the properties of various PMCs and to design new systems with even more interesting and useful properties.

Nanoparticles with various shapes and structures are known as promising materials for various engineering applications and to promote the performance of polymer matrices, which have been extensively examined in PCRG during recent years. Currently we focus on developing hybrid nanoparticles by attaching two or more nanoparticles via chemical or even physical routes. Combing nanoparticles with different shapes, sizes and performances into a single nanohybrid enables us to obtain multifunctional materials with synergistic behaviors which is promising for current and future technologies. In PCRG, we examine such advanced and well-designed nanomaterials in various engineering applications such as water treatment, drug/gene delivery, tissue engineering, shape memory polymers, wearable & flexible electronics, polymeric membrane and polymeric surface coating.

Processing issues of advanced composite manufacturing techniques like Resin Transfer Molding (RTM) and its different variants such as vacuum assisted RTM (VARTM) are also our research interests. Numerical simulation of flow through fibrous media is a constructive tool to design RTM/VARTM. We use in-house computer codes or even general engineering softwares to simulate resin flow through fibrous media with complex mold geometry considering nonisothermal effects during mold filling process.

Due to the complexity of the morphology of composite materials originated from the morphological complexity of polymer matrices themselves, dispersion state of the reinforcing particles in polymer matrices and interactions at interface between polymer and particle in PMCs, correlation between the properties and the morphology has prime importance. In many cases, the reinforcing particles (particularly the nanoscale particles) have dominant role on the morphological features of polymer matrices such as the crystallinity and trans-crystallinity, morphology of polymer blends, promotion of immobilized polymer layer at interface. To overcome difficulties associated with morphological issues of PMCs, we focus on tailoring surface chemistry of reinforcing particles and controlling processing techniques. A basic knowledge on the structure-property relationship enables us to understand fundamentally the properties of various PMCs and to design new systems with even more interesting and useful properties.

Nanoparticles with various shapes and structures are known as promising materials for various engineering applications and to promote the performance of polymer matrices, which have been extensively examined in PCRG during recent years. Currently we focus on developing hybrid nanoparticles by attaching two or more nanoparticles via chemical or even physical routes. Combing nanoparticles with different shapes, sizes and performances into a single nanohybrid enables us to obtain multifunctional materials with synergistic behaviors which is promising for current and future technologies. In PCRG, we examine such advanced and well-designed nanomaterials in various engineering applications such as water treatment, drug/gene delivery, tissue engineering, shape memory polymers, wearable & flexible electronics, polymeric membrane and polymeric surface coating.

Processing issues of advanced composite manufacturing techniques like Resin Transfer Molding (RTM) and its different variants such as vacuum assisted RTM (VARTM) are also our research interests. Numerical simulation of flow through fibrous media is a constructive tool to design RTM/VARTM. We use in-house computer codes or even general engineering softwares to simulate resin flow through fibrous media with complex mold geometry considering nonisothermal effects during mold filling process.

Responsive & Smart Materials

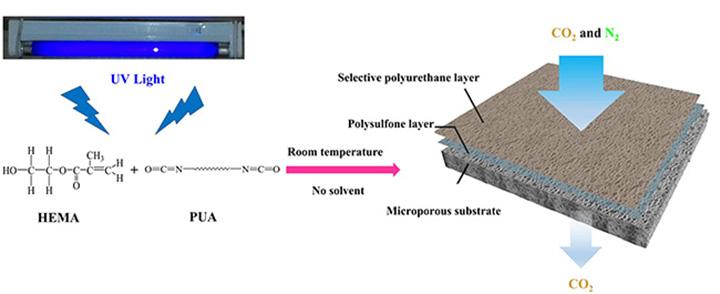

Polyurethane composites for separation of CO2

Increment of carbon dioxide production from fossil fuels is one of the main concerns of the current era. Trapping and storing carbon dioxide from the great productive resources is one of the most important ways to prevent entry of this gas into the atmosphere. Membrane separation is worth noticing as an energy efficient and economical tool in gas separation applications. Because of their outstanding features, such as reduced energy consumption, low capital cost, stability at high pressures, operation simplicity, easy scalability, compact system, easy processing and mechanical strength. One of the problems in the preparation of polymeric membranes on a large scale is to remove solvents from the membrane after processing. Development of polymeric membrane with no need for solvent can be promising in view point of processing and energy saving. UV-curable polymeric membranes have potential to become cross-linked in ambient temperature under UV radiation without need of solvent.

Increment of carbon dioxide production from fossil fuels is one of the main concerns of the current era. Trapping and storing carbon dioxide from the great productive resources is one of the most important ways to prevent entry of this gas into the atmosphere. Membrane separation is worth noticing as an energy efficient and economical tool in gas separation applications. Because of their outstanding features, such as reduced energy consumption, low capital cost, stability at high pressures, operation simplicity, easy scalability, compact system, easy processing and mechanical strength. One of the problems in the preparation of polymeric membranes on a large scale is to remove solvents from the membrane after processing. Development of polymeric membrane with no need for solvent can be promising in view point of processing and energy saving. UV-curable polymeric membranes have potential to become cross-linked in ambient temperature under UV radiation without need of solvent.

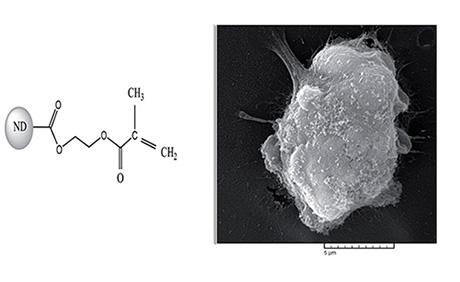

UV curable polyurethane nanocomposites for hard tissue engineering

Biodegradable and biocompatible acrylate-terminated polyurethane (APU) is an injectable polymer which can be considered as potential material for bone regenerative applications. When carbon based nanoparticle like nanodiamond (ND) and carbon nanotube (CNT) is added to APU, the mechanical properties enhance making this polymer much suitable for hard tissue engineering. However, APU reinforced with ND functionalized with acrylate groups (like HEMA) exhibit better performance because biocompatibility of neat APU retains by incorporation of ND while the mechanical properties are improved considerably.

Biodegradable and biocompatible acrylate-terminated polyurethane (APU) is an injectable polymer which can be considered as potential material for bone regenerative applications. When carbon based nanoparticle like nanodiamond (ND) and carbon nanotube (CNT) is added to APU, the mechanical properties enhance making this polymer much suitable for hard tissue engineering. However, APU reinforced with ND functionalized with acrylate groups (like HEMA) exhibit better performance because biocompatibility of neat APU retains by incorporation of ND while the mechanical properties are improved considerably.

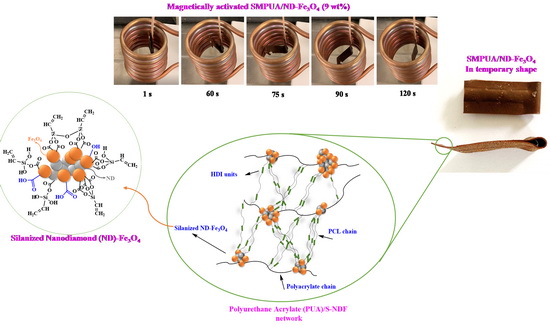

Shape memory biocompatible polyurethane acrylate/carbon-magnetic hybrid nanocomposites

Smart bio-based shape memory polymers (SMPs) with high performance and fast response have the exciting potential to meet the growing need in biomedical applications. Magnetically responsive SMPs have received lots of attention in the biomedical applications, especially the non-contact triggering of medical equipment and implants inside the body. In this research, the biocompatible nanocomposite based on shape memory polyurethane acrylates (SMPUAs)/ hybrid carbon-magnetic nanoparticles, as magneto-responsive SMPs for the biomedical applications, were synthesized using in-situ polymerization followed by UV and thermal curing. At the first step, the versatility of our UV-cured SMPUAs was reflected in good thermally activated shape memory performance (higher than 97% fixity and recovery) with fast response as well as tunable transition temperature. Furthermore, the synthesized nano-hybrid based on oxidized nanodiamond (Ox-ND)/ Fe3O4 nanoparticles in this study were characterized as highly biocompatible multifunctional nanostructures with superparamagnetic and luminescent properties. Finally, thermally cured PUA/(Ox-ND/Fe3O4) nanocomposites exhibited excellent shape recovery rate (above 96%) in a very small magnetic field.

Smart bio-based shape memory polymers (SMPs) with high performance and fast response have the exciting potential to meet the growing need in biomedical applications. Magnetically responsive SMPs have received lots of attention in the biomedical applications, especially the non-contact triggering of medical equipment and implants inside the body. In this research, the biocompatible nanocomposite based on shape memory polyurethane acrylates (SMPUAs)/ hybrid carbon-magnetic nanoparticles, as magneto-responsive SMPs for the biomedical applications, were synthesized using in-situ polymerization followed by UV and thermal curing. At the first step, the versatility of our UV-cured SMPUAs was reflected in good thermally activated shape memory performance (higher than 97% fixity and recovery) with fast response as well as tunable transition temperature. Furthermore, the synthesized nano-hybrid based on oxidized nanodiamond (Ox-ND)/ Fe3O4 nanoparticles in this study were characterized as highly biocompatible multifunctional nanostructures with superparamagnetic and luminescent properties. Finally, thermally cured PUA/(Ox-ND/Fe3O4) nanocomposites exhibited excellent shape recovery rate (above 96%) in a very small magnetic field.

Energy storage

Supercapacitors

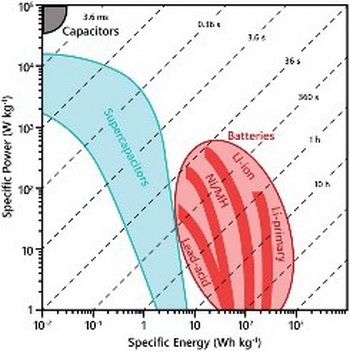

Supercapacitors, also called ultracapacitors or electrochemical capacitors, are promising energy storage devices and have attracted extensive attention due to their high power density, rapid charge-discharge process, and long cycle life. With higher power density than batteries and larger energy density than conventional capacitors, they bridge the gap between conventional capacitors and rechargeable batteries. We are currently focused on the development of nanocomposites based on conductive polymers and different hybrids of metals, metal oxides, and carbonaceous nanomaterials as electrode materials to enhance the specific capacitance, energy, and power density, and cycle life of the supercapacitors.

Supercapacitors, also called ultracapacitors or electrochemical capacitors, are promising energy storage devices and have attracted extensive attention due to their high power density, rapid charge-discharge process, and long cycle life. With higher power density than batteries and larger energy density than conventional capacitors, they bridge the gap between conventional capacitors and rechargeable batteries. We are currently focused on the development of nanocomposites based on conductive polymers and different hybrids of metals, metal oxides, and carbonaceous nanomaterials as electrode materials to enhance the specific capacitance, energy, and power density, and cycle life of the supercapacitors.

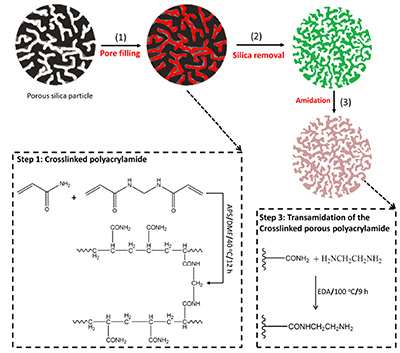

Environmental

Polymeric and

polymeric

composites as efficient adsorbents of dyes from aqueous solutions

Adsorption by suitable adsorbents is versatile and cost-effective method for dye removal from aqueous solution and wastewater treatment. Currently, we are focused on development of efficient polymeric systems with enhanced adsorption capacity. The attempts are made to tune surface chemistry of the polymeric adsorbents, enhancement of specific surface area by controlling the microstructure of polymer particles, inclusion of nanoparticles in suitable polymeric systems (polymeric nanocomposites), etc.

Adsorption by suitable adsorbents is versatile and cost-effective method for dye removal from aqueous solution and wastewater treatment. Currently, we are focused on development of efficient polymeric systems with enhanced adsorption capacity. The attempts are made to tune surface chemistry of the polymeric adsorbents, enhancement of specific surface area by controlling the microstructure of polymer particles, inclusion of nanoparticles in suitable polymeric systems (polymeric nanocomposites), etc.

Friction Materials

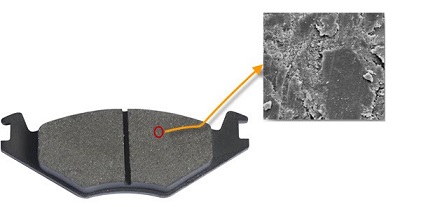

Brake friction materials

The PCRG has long-term experience on the brake friction materials formulation. Normally, brake friction materials consist of many ingredients such as fibers, metals, abrasives, lubricants and fillers which are distributed in thermosetting matrices such as phenolic resin or its derivatives. The current research interests in PCRG is mainly focused on development of various classes of non-asbestos and environmental-freindly brake friction materials including low steel friction formulations, non-asbestos organic (NAO) friction materials, copper free friction materials and rubber based friction materials for wide range of braking systems from trains in railroads to light vehicles in roads. Special attention is presently taken into account for the use of nanoparticles to improve wear resistance, fade behavior and braking performance.

Brake friction materials

The PCRG has long-term experience on the brake friction materials formulation. Normally, brake friction materials consist of many ingredients such as fibers, metals, abrasives, lubricants and fillers which are distributed in thermosetting matrices such as phenolic resin or its derivatives. The current research interests in PCRG is mainly focused on development of various classes of non-asbestos and environmental-freindly brake friction materials including low steel friction formulations, non-asbestos organic (NAO) friction materials, copper free friction materials and rubber based friction materials for wide range of braking systems from trains in railroads to light vehicles in roads. Special attention is presently taken into account for the use of nanoparticles to improve wear resistance, fade behavior and braking performance.

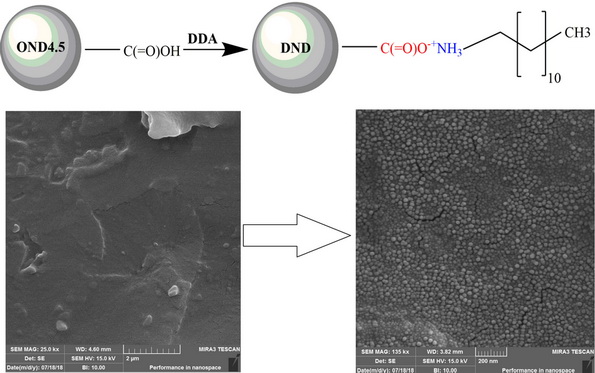

ND loaded inhibitor as efficient nanocarrier for epoxy coating

Incorporating nanofillers well-dispersed in the polymeric matrix is suggested to improve barrier properties of epoxy coating against corrosive environments. In this regard, nanodiamond (ND) owning tunable surface as well as the high specific surface area is a suitable candidate. However, nanoparticles agglomeration caused by reactive hydrophilic groups on the ND surface restricts its use within the anticorrosion coatings. To cope with this limitation, Dodecyclamine (DDA) surfactant modified ND terminated to the hydrocarbon tail, not only interact easily with polymer chains but also donate hydrophobic behavior to the coating, leading to lowering corrosive species diffusion into the polymeric matrix.

Incorporating nanofillers well-dispersed in the polymeric matrix is suggested to improve barrier properties of epoxy coating against corrosive environments. In this regard, nanodiamond (ND) owning tunable surface as well as the high specific surface area is a suitable candidate. However, nanoparticles agglomeration caused by reactive hydrophilic groups on the ND surface restricts its use within the anticorrosion coatings. To cope with this limitation, Dodecyclamine (DDA) surfactant modified ND terminated to the hydrocarbon tail, not only interact easily with polymer chains but also donate hydrophobic behavior to the coating, leading to lowering corrosive species diffusion into the polymeric matrix.